Rubber vulcanisation is a chemical process that involves treating natural rubber or other elastomers with sulfur or other crosslinking agents to improve their physical properties. Vulcanisation makes rubber stronger, more durable, and more resistant to abrasion, temperature, and chemicals.

How Is Rubber Vulcanised?

The process of rubber vulcanisation involves heating the rubber with sulfur or other crosslinking agents. Vulcan heating causes the crosslinking agents to form chemical bonds between the rubber molecules, creating a three-dimensional network structure. This network structure gives the rubber its improved properties, such as increased strength, elasticity, and resistance to abrasion.

The vulcanisation of rubber can be carried out using several methods, including compression molding, injection molding, and extrusion. In compression molding, the rubber is placed into a mold, and heat and pressure are applied to shape and vulcanise the rubber. Injection molding involves injecting the rubber into a mold under high pressure and heat. Extrusion involves pushing the rubber through a die to create a specific shape.

What are some advantages of vulcanisation?

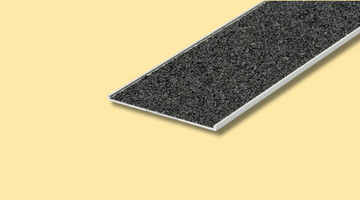

Wheel stops made from vulcanised rubber offer several advantages.

- First, they are more durable than wheel stops made from non-vulcanized rubber, which can crack and break over time. Vulcanised rubber wheel stops are also more resistant to wear and tear from constant use and exposure to the elements. They are also more resistant to UV rays, which can cause non-vulcanized rubber to deteriorate over time.

- Second advantage of vulcanised rubber wheel stops is that they provide better traction. The three-dimensional network structure created during vulcanisation provides a textured surface. It can help prevent vehicles from slipping or sliding. This is particularly important in areas with wet or icy conditions, where the risk of accidents can be higher.

These benefits make these kinds of wheel stops an excellent choice for parking lots and other areas where vehicles need to be parked safely and securely.

Contact eSafety Supplies today to Enhance Safety & learn more about their range of eSafety wheel stops and how they can benefit your business, workplace, or community.